Aug 05,2025

Large size = large noise?

Quiet as a whisper, yet still brings coolness

Energy saving 30% Noise reduction 40% Double the coolness

My ears are finally saved!

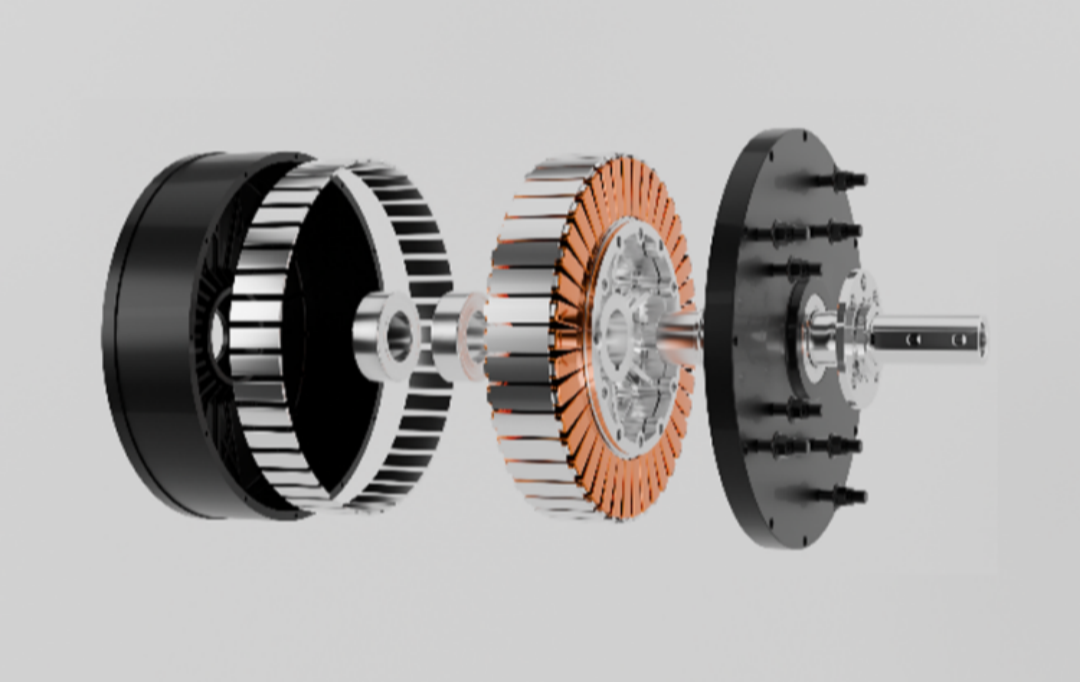

01. Power System

1. PMSM Permanent Magnet Synchronous Motor:

PMSM uses permanent magnet excitation; the rotor requires no current, reducing rotor harmonic magnetic field pulsation. When an asynchronous motor is frequency-converted, the axial voltage discharge produces electrical erosion noise (“clicking sound”). PMSM, due to rotor insulation, reduces this type of noise.

2. Dynamic noise reduction of frequency conversion control:

Low-noise operation, optimized algorithm control for stable start-up.

02. Blade Design

1. Streamlined variable cross-section fan blade design:

Through aerodynamic simulation analysis, applying equal chord length theory, combined with the principle of relative linear velocity, a streamlined variable cross-section airfoil fan blade was developed and designed.The blade gradually narrows and thins from root to tip, resulting in more balanced force, more uniform air delivery, and no central cavity.

2. Noise reduction characteristics of aviation-grade materials:

It has high damping characteristics, reducing vibration and noise. The aerodynamic noise generated by the blades during rotation is lower, and it can avoid frequency bands sensitive to the human body, thereby reducing noise.

3.5-blade design

Axisymmetric, avoiding resonance, improving dynamic balance stability, and significantly reducing operating noise

03. Vibration Reduction System

1. Vibration damping rubber

The entire stem is PU polyurethane coated—with high-precision matching with the blade buffer cavity, absorbing stress and airflow vibration from the blades, reducing motor load, and extending service life.

2. Multi-point riveting process:

16 high-strength steel core rivets are riveted separately above and below (a single rivet can withstand 1500KG of tensile force), forming independent upper and lower layers of blade force to withstand the strong centrifugal force when the fan is running at full speed.

In industrial and commercial environments, noise pollution can be a significant issue.

Traditional fans, especially when used in large numbers, can generate considerable noise.

High-volume, low-speed (HVLS) fans offer a quieter alternative while still providing the necessary airflow.