Jul 02,2025

In the factory, industrial fans deliver coolness,

But do you know that the hidden danger of falling fan blades,

is quietly threatening production?

The tensile strength defect of traditional bolt connections makes "fan blades flying out" an industry pain point.

Why are fan blades prone to "loss of control"?

In industrial environments, high-frequency operation of fans, continuous vibration, and environmental temperature differences cause thermal expansion and contraction, causing tearing and damage to traditional bolted connections, resulting in a decrease in tensile strength at the connection points, leading to a chain of failures such as thread slippage and fan blade loosening. High-speed fan blade loss of control will seriously threaten personnel and equipment safety.

Da Wang Ventilation HVLS Fan Safety Solution

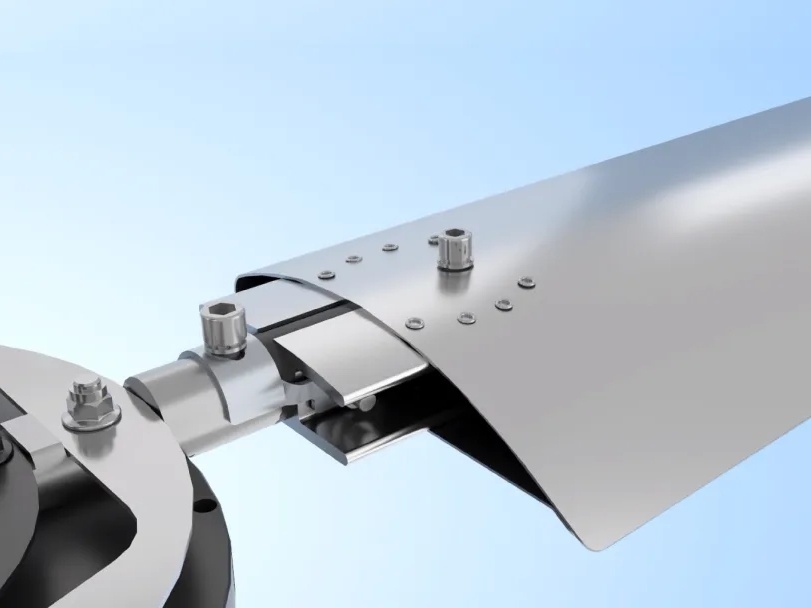

1. Abandon traditional bolts

One-piece blade stem + built-in buffer cavity design

Achieve structural integration, coupled with a 16-point matrix riveting design, a single rivet can withstand 1.5 tons of shear force, dispersing the load to reduce the risk of single-point overload failure.

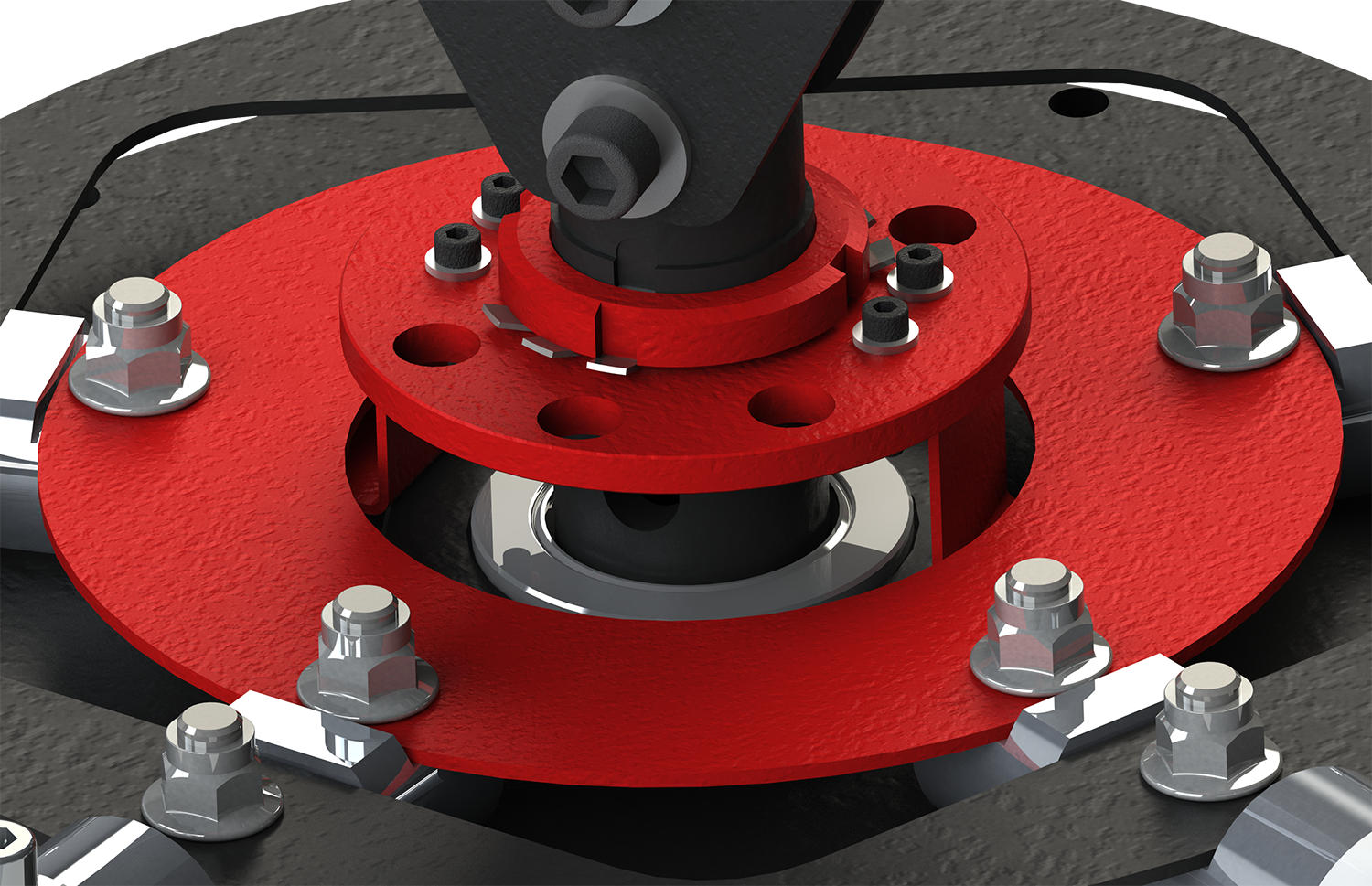

2. Inner cone bushing + anti-fall plate

Patented inner cone bushing + anti-fall plate

Forms a structural interlock with the motor output shaft, using gravity for natural tightening to ensure reliable connection; the anti-fall plate is fitted with the chassis, intercepting extreme situations such as wheel hub detachment and shaft breakage, building a dual-level anti-fall system.

3. Double certification of technology and reputation

Multiple protective designs are patented

Products have passed international authoritative certifications such as FCC, CE, ROHS, and UL!

10 years of zero fall records.

"Safety" is not an add-on, but a bottom line!

Da Wang Ventilation uses Design + Certification + Reputation Triple protection to build a protective barrier for every industrial space!