Oct 28,2025

As temperatures drop on October 1st, warm air rises toward the roof—hot at the top, cold below. But

when you try to turn up the heat, by month's end, the electricity bill ends up being painfully high again.

A dilemma—actually, there’s already a solution!

In winter, keeping the workshop warm while still saving on electricity costs hinges on the perfect "

industrial ceiling fan + heating equipment" combination—your solution to those core concerns.

Reduce the temperature difference

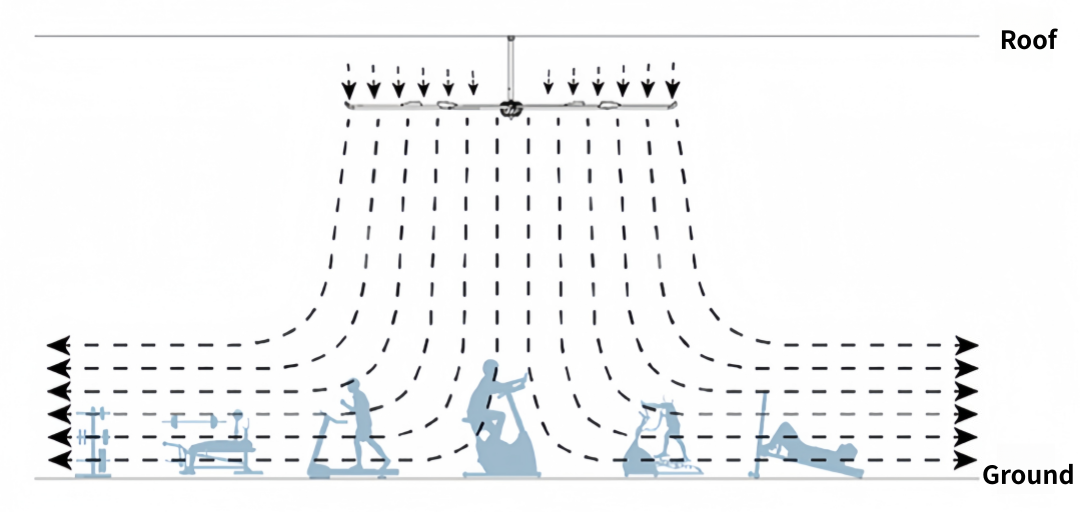

① Addressing the long-standing issue of "temperature stratification" in the workshop, the industrial ceiling fan operates smoothly at low speed,

effectively delivering the accumulated heat from the roof directly to the floor.

② Previously, the temperature difference between the top and the floor exceeded 8°C, but now it has been reduced directly to within 3°C. The

temperature is now evenly distributed across the workbench, corners, and areas alongside the production line.

③ Workers keep their hands from stiffening and their bodies from getting cold, allowing them to tighten screws and assemble parts quickly and

precisely—no longer hindered by the cold while working!

Save on electricity bills

① No need to rely on "aggressively turning up the heat" to maintain warmth—once the warm air is evenly distributed, simply lowering the

heating equipment by 2–3°C can significantly cut down on electricity bills.

② Energy savings can reach up to 30%, resulting in monthly electricity bill reductions of several thousand yuan.

The savings accumulated over the entire winter can cover more than half the cost of a

ceiling fan—warming the workshop while also keeping hard-earned money in your pocket.