Nov 26,2025

Una guía de mantenimiento gratuita en 3 pasos

Los ventiladores industriales grandes tienen pocos fallos.

¿Siente que los ventiladores industriales de techo Molestia de mantenimiento ?

En realidad, no requiere mucho esfuerzo. Sencillo Tres pasos ,

que pueden ayudar a mantener el ventilador de techo funcionando sin problemas y reducir problemas.

Antes de encenderlo, dedique 1 minuto a realizar una inspección visual desde el suelo.

1. Use el objetivo telefoto de su teléfono para capturar imágenes de las aspas del ventilador: verifique la presencia de acumulación importante de polvo, asegúrese de que los tornillos de las aspas no estén sueltos y confirme que la carcasa del motor no presente signos de daño.

2. Utilice el control remoto para arrancar el motor y girar suavemente las aspas del ventilador una vez, escuchando cuidadosamente cualquier sonido. Para los motores síncronos de imán permanente PMSM, "escuchar sonidos para detectar la posición" es más bien un mecanismo básico de alerta temprana: le ayuda a identificar posibles problemas antes de que empeoren. Si percibe ruidos sospechosos, la acción correcta es:

Registre: Documente el rango de RPM y los patrones en los que ocurre el ruido inusual.

Informe del problema: Comuníquese inmediatamente con personal técnico especializado en lugar de intentar solucionarlo usted mismo. El reajuste o reemplazo de los rodamientos de estos motores totalmente cerrados requiere herramientas y conocimientos especializados; intentar abrir el motor por su cuenta podría comprometer su clasificación de protección IP, anular la garantía e incluso crear riesgos potenciales de seguridad.

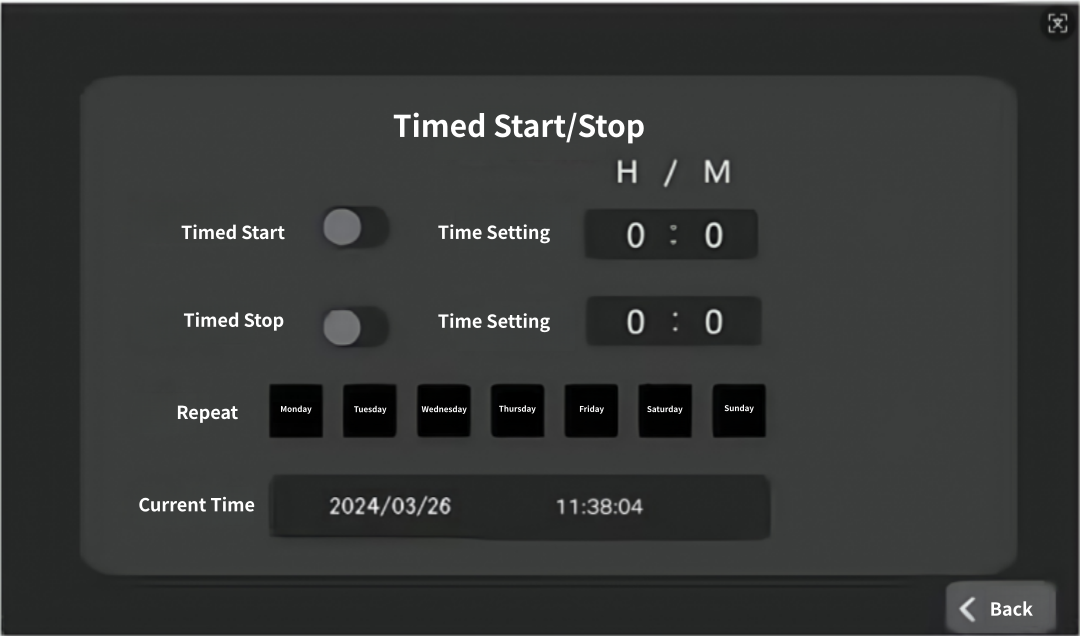

Funcionamiento: dedique 3 minutos a ajustar parámetros de forma remota.

El panel inteligente tiene un programa de arranque preestablecido que se activa automáticamente al encenderlo. Baja RPM Transferencia precalentamiento del motor de 5 minutos Luego, simplemente aumente hasta el régimen objetivo —no es necesario ajustar manualmente— y también puede evitar que el motor sufra sacudidas bruscas.

Después de apagarlo, dedique 5 minutos al mantenimiento en tierra.

01 Limpiar las palas del ventilador

Utilice un cepillo limpiador con mango extensible de 3 a 5 metros para limpiar las palas del ventilador: la electricidad estática atrae el polvo, eliminando la necesidad de lavado con agua.

02 Limpiar la carcasa del motor y los orificios de ventilación

Use un soplador de aire con boquilla extendida para limpiar cuidadosamente el polvo acumulado en la superficie de las aletas de enfriamiento de la carcasa del motor, y también limpie los orificios de ventilación en los conductos de aire de refrigeración externos. Esto garantiza una disipación eficiente del calor del motor —no es necesario desmontar la carcasa, lo que hace que el proceso sea rápido y cómodo.

03 Gestión anti-humedad

Instale sensores de temperatura y humedad en tierra, vinculándolos con el sistema de control.

Sigue estos tres pasos durante menos de 10 minutos y reducirás significativamente problemas comunes como la acumulación de polvo, tornillos sueltos y humedad en el motor, asegurando que tu ventilador industrial HVLS funcione más suave y dure más. Además, el ventilador industrial de Dawang Ventilation no solo ofrece un flujo de aire potente, sino que también hace que el mantenimiento sea muy sencillo.