Nov 18,2025

Ontleding van Algemene Probleme met Hoë-Krag Industriële Ventilators

Eerstens moet ons die konsep van hoë-vermoeiens industriële ventilators verstaan voordat ons die probleemanalise begin.

Die hoë-vermoeiens industriële ventilator is 'n energie- doeltreffende werkswinkelverkoelingstoestel wat relatief min elektrisiteit verbruik. Met 'n massiewe deursnee van 7,3 meter kan 'n enkele industriële ventilator effektief 'n oppervlakte van ongeveer 1 600 vierkante meter dek, wat dit die voorkeur maak vir groot ruimtes met hoë plafonne.

Tweedens moet ons ook die toepassings verstaan waarbinne hoë-vermoeiens industriële ventilators gebruik word. Dit is gewoonlik groot venues met relatief hoë en oop strukture, insluitend verskillende openbare ruimtes soos bus- en treinstasies, hawens, lughawens, sportstadions, kommersiële strate, winkelsentrums, skoolaudea, gimnasiums, ontspanningsklubs, internetkoffiewinkels, regeringsdienstehowes, en meer – in wese enige plek met beduidende voetgangersverkeer.

Nou dat ons die konsep en toepassingssenario's van industriële ventilators ondersoek het, kan ons voortgaan om 'n paar algemene vrae oor hoë-vermogen industriële ventilators te beantwoord—sowel as veiligheidsoorwegings te bespreek.

01. Is dit nodig om hoë-vermogen industriële ventilators in fabriekswerkswinkels te installeer? En hoe verskil hulle van lugverkoelers?

1. Tans bestee die nasie en samelewing groot aandag aan en heg groot belang aan die basiese regte van nywerheidswerkers. Ondertussen neem werkers se verwagtinge ten opsigte van hul werkomskep geleidelik toe. Gevolglik het werknemeromset toenemend algemeen geword, en het die werf van nuwe personeel 'n volgehoue uitdaging geword. Wetenskaplike navorsing toon dat werkers in warm en vochtige omgewings geneig is om makliker prikkelbaar te voel, wat nie net hul produktiwiteit verminder nie, maar ook die waarskynlikheid van foute by die werk verhoog. Daarom is die verbetering van werkers se gerief tydens die brandende somermaande 'n kritieke kwessie wat sakeondernemings—en hul bestuurspanne—ernstig moet oorweeg.

Op hierdie punt kan iemand vra: "Waarom installeer jy dan nie lugverkoeling nie, in plaas van 'n hoë-vermoe industriële ventilator?"

Wel, ons moet praat oor sommige van die nadele van lugverkoeling in hierdie omstandighede. Eerstens, die lugvloei imiteer nie natuurlike, alomteenwoordige briesies nie—dus kan langdurige blootstelling maklik lei tot 'lugverkoelingsiekte'. Tweedens verbruik lugverkoeleers 'n beduidende hoeveelheid elektrisiteit, terwyl hoë-vermoe industriële waaier veel minder energie gebruik in vergelyking met industriële lugverkoelingsisteme. En laastens, en die belangrikste, is daar die veiligheidskwessie: in omgewings met swaar voetgangersverkeer, kan die vogtige toestande wat deur lugverkoeling geskep word, die risiko van elektriese skok dramaties verhoog.

Daarom is die installering van hoë-vermoe industriële waaier 'n betroubare en koste-effektiewe oplossing wat nie net die omgewing koeler hou nie, maar ook werknemers se klagtes oor die toestande elimineer, wat uiteindelik hul produktiwiteit verhoog.

Dit is 'n wen-wen-oplossing!

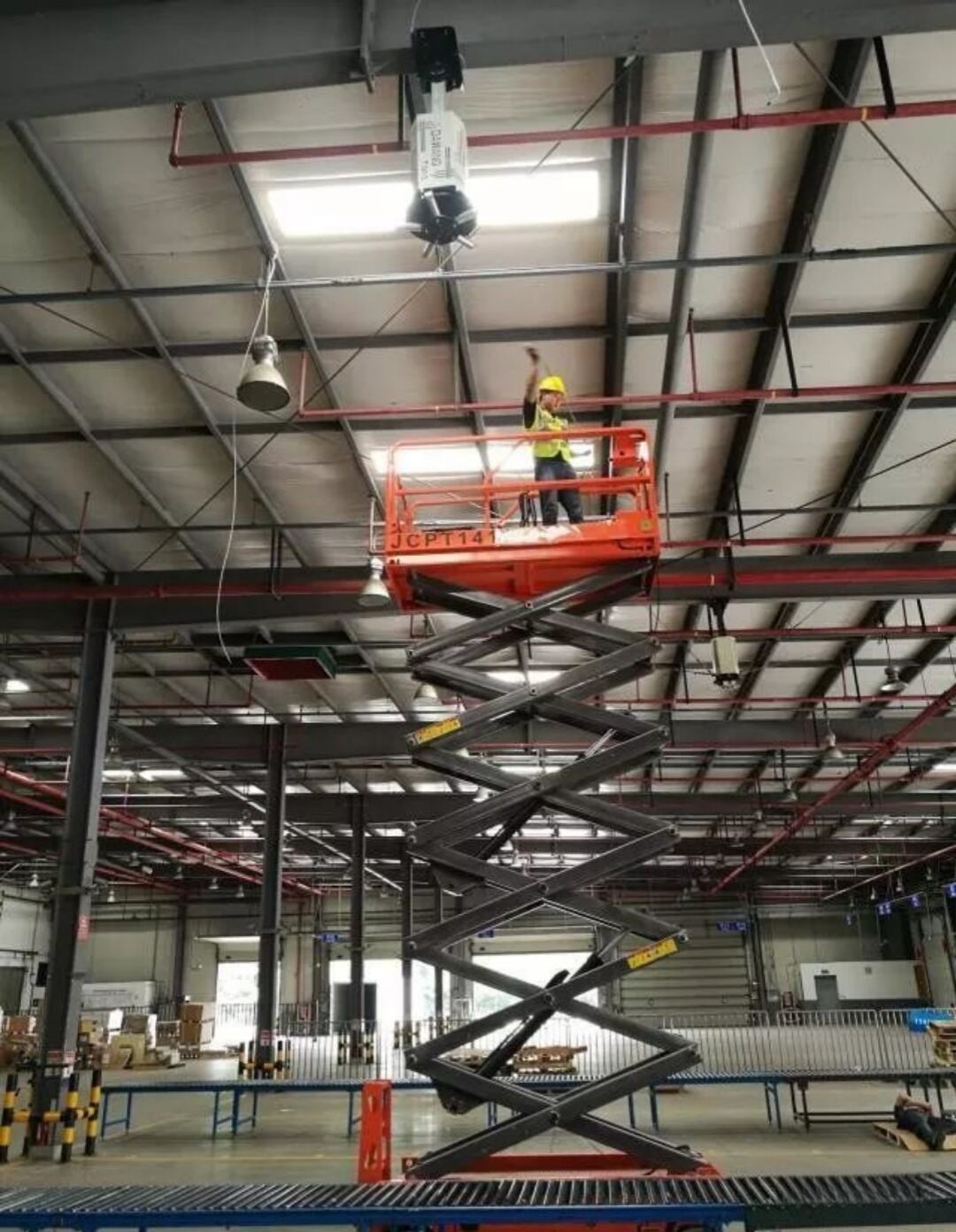

02. Wat is die installasievereistes vir hoë-krag industriële ventilators? Is dit veilig om hoë-krag industriële ventilators op verhoogde hoogtes te installeer?

1. Die installasievereistes vir hoë-krag industriële ventilators is baie veelsydig—solang jou geboustruktuur aan die volgende kriteria voldoen: H-balks, I-balks, staal-beton saamgestelde balks, sferiese kolomme en ander soortgelyke strukture; die totale gebouhoogte moet meer as 4,5 meter wees; die ventillerskragte moet 'n minimum veiligheidsafstand van 0,2 meter van enige hindernisse handhaaf; en die ingangsenergievoorsiening moet in staat wees om óf 380V of 220V te hanteer.

2. Deur noukeurige terreininspeksies en die implementering van verskeie veiligheidsmaatreëls, verseker ons dat die ventilator veilig en betroubaar op hoë hoogtes werk. Professionele ingenieurs word gestuur om die installasie-omstandighede ter plekke te bepaal en die draagkrag van die balks te bereken, en sodoende te bevestig dat die veiligheidsfaktor bokant die gespesifiseerde standaard is voordat die installasie begin. Die volledige masjienstruktuur en installasieproses sluit verskeie vlakke van veiligheidsbeskerming in, insluitend:

①. Boonste balk met staaldraadomhulsel-beskerming om valle te voorkom.

②. Vier staaldraade verskaf gebalanseerde beskerming; 'n valbeveiligingsring voorkom asbreuk en skeiding, en voorkom dus valle.

③. Motor- en vliegwiel anti-val selfsluittoestel verseker die betroubare vasgord van die wielembo en uitsetas saam.

④. Geïntegreerde eenvoudige wielembo wat trekragte oorsteekend 11 ton kan weerstaan.

⑤. Die mortise-en-pen blaarsteel verbind met die naaf, wat voorkom dat die lem opwaarts krul, afwaarts hang of heen en weer swaai.

⑥. Beskermingsmaatreëls vir waaiervleuels: 'n Veiligheidsverbindingsketting beveilig die waaiervleuels laag vir laag stewig, sodat hulle as een eenheid bymekaar gehou word om te voorkom dat hulle losraak.

⑦. Aktiveer outomaties 'n alarm en stop die werking om ongelukkige beserings te voorkom.

03. Wat is die voordele van hoë-vermogen industriële waaier?

1. Vleuelmateriaal: 'n Hoë-gradige, 5052 aluminiumlegeringplaat met 'n dikte van 1,5 mm—wat in die lugvaartindustrie gebruik word—vanweë sy oorheersende digtheid en sterkte. Hierdie vliegtuigspesifieke aluminiumplaat bied verbeterde sterkte en buigsaamheid, wat sorg vir 'n blink, duursame afwerking.

2. Dwarsdoorsnitvorm van die vleuel: Gestroomlynde, veranderlike-profielontwerp wat voldoen aan die gelyke-koordlengte-teorie van aërodinamika, wat sorg vir meer eenvormige lugvloei, groter algehele lugvolume, en geen middelgaps nie.

3. Petiool-bladverbinding: Toetsing deur 'n professionele instelling bevestig dat die hele blad trekragte wat meer as 1,7 ton oorskry, kan weerstaan, wat die blad se aanhegting tot die enigste veiligheidskenmerk van die blad maak.

4. Trilgedempende rubberplate vir isolasie: Tril-geïsoleerde rubberplate is tussen die naaf montagegatte en spesiaal gevormde insetsels geplaas, wat 'n nie-rigiede verbinding tussen die lemstam en die chassisnaaf moontlik maak.

5. Kernpatent: Die verbindingskomponente van die DaWang hoë-krag industriële ventilator het almal 'n mortise-en-tong ontwerp. Dit sluit veral die verbinding tussen die interne keël en die motor, die aansluiting van die wielbord met die lemstam, en die aanhegting van die lemstam aan die dempingsmeganisme in — wat effektief die algehele veiligheid van die ventilator verseker.

Nadat ons basiese kennis oor groot industriële ventilators opgedoen het, sal ons die belangrikheid van hul installasie in daardie hoë, benoude ruimtes verstaan – en leer hoe om 'n industriële ventilator te kies wat uitblink in alle sleutel prestasie-areas. Hierdie benadering help nie net om koste te verminder nie, maar verseker ook maksimum veiligheid.